The characteristics of eight categories of rubber accelerators and their commonly used rubber accelerators interchange relationship (synergy, inhibition)

Release time:

2018-07-12

According to the different chemical structures, accelerators can be divided into thiazoles, thiuram, sulfonamides, guanidines, dithiocarbamates, aldehydes, amines, xanthates and thioureas. 1. thiazoles This is an earlier variety of organic accelerators. Belong to acid accelerator. It is characterized by high vulcanization activity, which can give vulcanized rubber good aging resistance and fatigue resistance. Therefore, it is widely used in the rubber industry and consumes a large amount. There are two main varieties as follows. (1)2 Thiol Benzothiazole Trade name Promoter M. This product is light yellow powder, bitter taste, non-toxic, storage stability.

According to the different chemical structures, accelerators can be divided into thiazoles, thiuram, sulfonamides, guanidines, dithiocarbamates, aldehydes, amines, xanthates and thioureas.

1. thiazoles

This is an earlier variety of organic accelerators. Belong to acid accelerator. It is characterized by high vulcanization activity, which can give vulcanized rubber good aging resistance and fatigue resistance. Therefore, it is widely used in the rubber industry and consumes a large amount. There are two main varieties as follows.

(1)2 Thiol Benzothiazole Trade name Promoter M. This product is light yellow powder, bitter taste, non-toxic, storage stability. It is a general-purpose accelerator, which has a rapid promotion effect on natural rubber and diene general-purpose synthetic rubber, good vulcanization flatness, vulcanization critical temperature of 125 ℃, and the possibility of encephalitis burning when mixing. It is easy to disperse in rubber and does not pollute, but it is not suitable for rubber products for food. The first accelerator is used in an amount of 1 to 2 parts, and the second accelerator is used in an amount of 0.2 to 0.5 parts. Can also be used for natural rubber peptizer.

(2) Dibenzothiazole disulfide The trade name is Accelerator DM. This product is light yellow powder, bitter, non-toxic, stable during storage. Its characteristics and uses are similar to M, but the critical temperature of vulcanization is 130 ℃. The activity increases above 140 ℃, has good aftereffect, and the vulcanization operation is safe. Often with other promoters and to improve its activity.

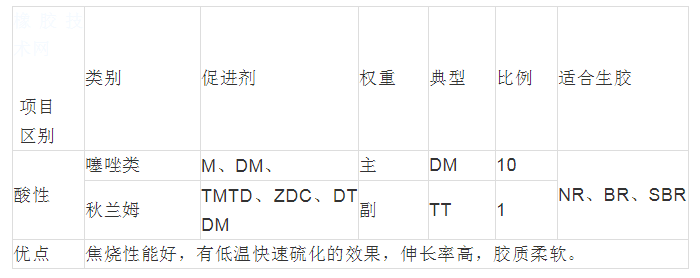

2. Qiulam

Such accelerators are acidic. It belongs to the overspeed accelerator. Including a sulfide Qiulam, two sulfide Qiulan and more sulfide Qiulan. Thiuram disulfide can be used for sulfur-free yellow vulcanization with a vulcanizing agent. As an accelerator is generally used as a second accelerator, and thiazole and sulfenamide accelerators are used to increase the vulcanization speed. When used in combination with sulfenamide accelerators, it can delay the time when the rubber starts to react, and the reaction can proceed very quickly after the vulcanization starts, and the vulcanization degree of the vulcanized rubber is also relatively high. This production system is particularly important in low sulfur vulcanization. The physical and mechanical properties and aging resistance of vulcanizates using thiuram accelerator are affected by the proportion of accelerator and sulfur. Generally speaking, the amount of sulfur is normal, the tensile strength of the vulcanizate is higher, and other physical and mechanical properties are better; when the amount of sulfur is lower and the amount of promotion is larger, the heat aging resistance of the vulcanizate can be improved. The most commonly used type of thiuram accelerator is tetramethylthiuram disulfide, the trade name is accelerator TMTD, referred to as accelerator TT. It can be used as an accelerator or as a vulcanizing agent. When used as an accelerator, the dosage is generally 0.2 to 0.3 parts.

3. Sulfenamides

This is a class of late-acting accelerators that are acidic. It has the characteristics of long scorch time and high vulcanization activity. The vulcanization degree of vulcanized rubber is relatively high, the physical and mechanical properties are excellent, and the aging resistance is quite good. The compound has a wide vulcanization flatness. Due to the development and extensive application of synthetic rubber and the popularization and application of high-dispersion furnace carbon black, there is a special demand for accelerators with good late-acting properties. Therefore, this kind of accelerator occupies a very important position and has become the fastest growing and most promising type of accelerator in recent years. At present, among the various accelerators used in the world, the remote is mainly secondary sulfonamides, among which CZ, NOBS, NS, DZ and OTOS are widely used, all of which are derivatives of thiol benzothiazole.

(1) N-Cyclohexyl-2-benzothiazolylsulfenamide Trade name Accelerator CZ. This product is light yellow powder, slightly odor, non-toxic, specific gravity of 1.31~1.34, melting point of not less than 94 ℃, storage stability. The critical temperature of vulcanization is 138 ℃, which has the advantages of excellent anti-scorch performance and fast vulcanization speed. This product is slightly discolored, for the spray frost, vulcanized rubber has excellent aging resistance. The general dosage is 0.5~2 parts.

(2)N-oxydiethylene-2-benzothiazole sulfenamide or 2-(4-morpholinylthio) benzothiazole is known as the accelerator NOBS. This product is light yellow powder, non-toxic. The proportion is 1.34~1.40. The melting point is 80 ℃ ~ 86 ℃. Gradually decompose when exposed to heat, so it should be stored at low temperature. When the storage time is more than 6 months, the scorch of the compound increases, the critical temperature of vulcanization is above 138 ℃, the scorch time is longer than that of the accelerator CZ, and the operation is safer. This product is easy to disperse in the rubber, no spray frost, slight discoloration. The general dosage range is 0.5~2.5 parts, and with 2~0.5 parts of sulfur.

(3)N-tert-butylbenzothiazole sulfenamide trade name accelerator NS. This product is light yellow powder with special smell. The specific gravity is 1.29 and the melting point is not lower than 105 ℃. Its performance and usage are basically similar to the accelerator CZ, but it has greater delay in natural rubber. This product is slightly discolored and pollution.

(4)N, N-dicyclohexyl-2-2 benzothiazole sulfenamide trade name accelerator DZ. This product is brown yellow powder, odorless. The specific gravity is 1.2. The melting point is not lower than 90 ℃. Storage stability. This product has good dispersion in rubber. The vulcanization flatness is similar to that of the accelerator CZ. The dynamic physical and mechanical properties of the vulcanizate are better, and the elasticity and constant elongation strength are high. However, due to the bitter taste of the vulcanizate, it cannot be used to make products in contact with food. The dosage range is generally 0.5~1 parts, sulfur is 2.5 parts.

4. Guanidines

This kind of accelerator is alkaline, and the medium speed accelerator is used earlier. Vulcanization flatness is poor, the starting point of vulcanization is slow, the scorch time is short, the safety of vulcanization operation is poor, and it has pollution. It is rarely used alone or as a first accelerator. General and as the second accelerator. The tensile strength and rebound rate of the vulcanizate are relatively high, and the heat generation is low. The main varieties commonly used are diphenylguanidine, the trade name is accelerator D or accelerator DCP. This product is white powder, non-toxic, but irritating when in contact with the skin, the proportion is 1.13~1.19. The melting point is not lower than 144 ℃. The critical temperature of vulcanization is 141 ℃, and the vulcanization flatness is poor. Pollution, not suitable for white light-colored products and rubber products in contact with food. When the first accelerator is used, the amount is 1-2 parts, and when the thiazole accelerator is used as the second accelerator, the amount is 0.1-0.5 parts.

5. dithiocarbamates

This is a kind of super speed accelerator, which is acidic. The vulcanization speed is particularly fast, the flat range of the vulcanization curve is small, and the scorch time is short, so the rubber material is prone to early vulcanization during processing, and the vulcanization operation is not safe. Vulcanization conditions are not properly mastered, it is easy to occur under sulfur or over sulfur phenomenon. If used properly, the physical and mechanical properties and aging resistance of vulcanized rubber are superior, no pollution. It is suitable for the vulcanization of thin products with high temperature and short time vulcanization, room temperature vulcanization products and latex products. The most commonly used zinc salt varieties are as follows: zinc dimethyl dithiocarbamate trade name is accelerator PZ. Also known as accelerator ZDMC. This product is white powder, tasteless, non-toxic. But contact with the skin can cause inflammation. The proportion is 1.65~1.74. The melting point is 240~255 ℃. The critical temperature of vulcanization is about 100 ℃, and the vulcanization activity is similar to that of accelerator TT, but the activity is larger at low temperature and the tendency of scorching is large. This product is easy to disperse in rubber, tasteless, non-toxic, no pollution. Mainly used for rubber products, natural vulcanized glue, tape products and cold vulcanized products, light color and color products, edible rubber products. The amount used in the latex compound is generally 0.3 to 1.5 parts.

6. aldehyde amines

Such accelerators are condensates of aliphatic aldehydes or amines (aliphatic or aromatic amines). It is acidic. When the varieties are different, their vulcanization activity and the resulting vulcanization performance are quite different. Its activity generally ranges from quasi-super to slow levels. Have good flatness, scorch time is not long. The biggest feature is the excellent aging resistance of the resulting vulcanizate. Among them, the less active accelerator (such as hexamethylenetetramine) is mostly used as the second promotion of the thiazole or sulfenamide accelerator. Only butyraldehyde aniline condensate is a strong promoter, and is used as the first promoter when it is dispersed with the thiuram promoter.

(1) The trade name of hexamethylenetetramine is Accelerator H. This product is white to pale yellow crystalline powder, almost odorless, bitter taste. It has a stimulating effect on the skin. The specific gravity is 1.3. Heating to 263°C will sublimate and partially decompose. Slightly deliquescent. The critical temperature is 140 ℃, the vulcanization temperature is low, and the risk of scorching is small. Used as a second accelerator. No discoloration, no pollution, not easy to decompose. Mainly used for transparent and thick-walled products.

(2) n-butyraldehyde and aniline condensate trade name is accelerator 808. This product is brown red or amber viscous oily liquid with special smell. Specific gravity 0.94~0.98. In the air for a long time, the color becomes darker and the proportion increases. But the effectiveness is unchanged. Isolated from the air storage stability. The curing flatness is high, the critical temperature is 120 ℃, and the optimum curing temperature is 120~160 ℃. Good dispersion in dry glue. Suitable for rubber and hard rubber containing reclaimed rubber.

7. Xanthate

This is also a particularly active class of overspeed accelerators, the acceleration being even faster than the ammonium salts of dithiocarbamic acid. The vulcanization flat range is very small. Generally used for latex and low-temperature vulcanized mucilage, only special cases are used for dry glue. The commonly used variety is n-butyl xanthate zinc, and the trade name is accelerator ZBX. This product is white powder Lin, has a special smell, non-toxic. The specific gravity is 1.40. Heating is decomposition. There is a tendency to decompose slowly during storage, so it needs to be stored at low temperature (below 10 ℃). For super accelerator, no pollution.

8. thioureas

Other new varieties of accelerators are currently working on new types of accelerators in order to obtain accelerators with high vulcanization promotion efficiency, good processing safety, good anti-reversion properties, and high aging resistance. In addition, the variety of sulfur donors is gradually increasing, and non-sulfur crosslinking systems are emerging. And is recognized as toxic accelerators such as ethylene thiourea, etc. are being eliminated.

(1) Triazine accelerator is the most important of which is bis (2-ethyl amino -4-diethylamino triazinyl -6) disulfide. This product has higher promotion efficiency than ordinary accelerators, faster vulcanization speed, and safe processing. The vulcanization speed in natural rubber is similar to that of accelerator NOBS, and the processing safety is between NOBS and CZ. When the amount is small, in the natural rubber containing 1.5~2.35 parts of comb yellow, only 0.3 parts can replace 0.5 parts of sulfenamide. This accelerator can improve the anti-reversion properties of sulfur rubber at low sulfur dosage, and can be used in styrene-butadiene rubber, isoprene rubber and nitrile.

(2) thiocarbamyl sulfenamide such accelerators are mainly N-oxydiethylene thiocarbamyl-N-oxydiethylene sulfenamide, which has high operational safety, fast vulcanization speed and large promotion effect. Suitable for styrene-butadiene rubber, nitrile rubber, EPDM and other general synthetic rubber. An amount of 0.67 parts of the compound vulcanizes faster than with 1 part of the sulphonyl accelerator. And satisfactory operation safety performance can be obtained. The activity above 149°C is very large, while a small amount of promoter NOBS, M or DM can be added when it is lower than 149°C.

(3) Thiophosphoryl Accelerator Bis (diethylthiophosphoryl) trisulfide This accelerator can be used as a sulfur donor in natural rubber. Partial or total replacement of sulfur yellow can improve the heat resistance of vulcanized rubber, and improve the vulcanization reversion and compression deformation performance during high temperature vulcanization. EPDM rubber is an excellent accelerator, safe operation, fast vulcanization speed, excellent heat resistance and no spray, excellent compression deformation resistance. It is different from many other accelerators and sulfur and sulfur donors, and will not cause the degradation of polyester fibers when vulcanized in contact with rubber.

The Interchange Relationship of Common Rubber Accelerators

The exchange relation of accelerator

DM 1 = = 》 CZ 0.5-0.61

DM 1==》M 0.52-0.8

DM 1==》NOBS0.63-0.69

DM 1==》TMTD0.08-0.10

NOBS 1==》DM 1.43-1.6

NOBS 1==》TMTD 0.1

NOBS 1==》M 0.7-0.75

CZ 1==》NOBS 1.2-1.3

Acid accelerator; thiazole, thiuram, dithiocarbamate, xanthate.

Alkaline accelerators: guanidines and aldehyde amines.

Neutral accelerators: secondary yellow amides and thioureas

Quick Farewell

Slow grade: aldehyde amine, thiourea

Medium speed: guanidine

Quasi-overspeed grade: thiazole, secondary yellow amide

Speeding Level: Tulam

Super speed grade: dithiocarbamate, xanthate

A stands for acidic accelerator; B stands for basic accelerator; N stands for neutral accelerator

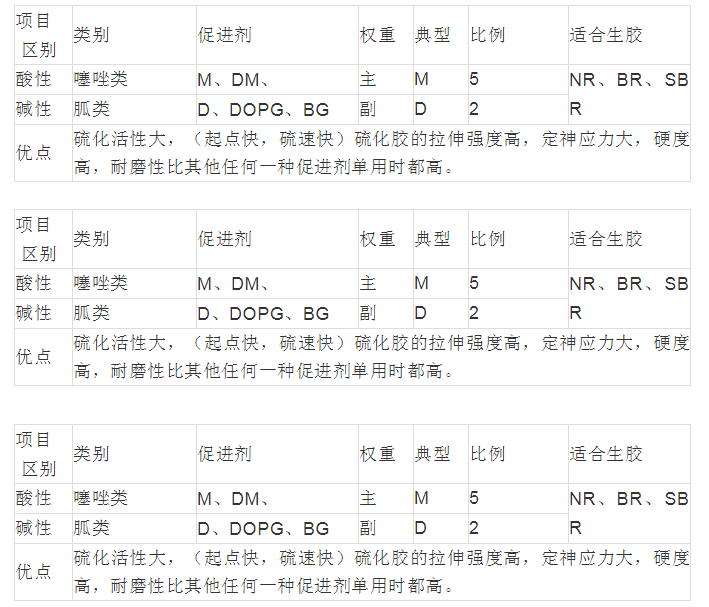

Acid-base combination (AB) coordination mechanism: mutual activation

(AA) coordination mechanism; mutual inhibition

Coordination mechanism of medium acid and (NA): unilateral activation

Key words:

Relevant Blog

Methods of bridge reinforcement

2018-08-13

Maintenance and cleaning of rubber molds

2018-08-13

Contact Us

Hotline:

+86-318-8885959

E-mail:

xiaoshoubu@hebeitaile.com

Address:

No.88, Industrial Street, North Industrial Base, Taocheng District, Hengshui City, Hebei Province

Website

Copyright © Hebei Taile Railway Equipment Co., Ltd